Since the Paris Climate Accord reached COP21, the world at large has focussed a lot of attention on climate change and the ways to curb its effects on the environment. The manufacturing sector, including the perfluorocarbon-spitting aluminium industry, too has committed to implementing effective ways to tackle the problem. They are resorting to automated recycling more intensively than ever to reduce the production of primary aluminium and increase the use of secondary aluminium instead. Aluminium recycling is expected to reduce the carbon footprint of the industry to a significant extent in the next ten years.

Aluminium recycling yields best results when every step, right from sorting and shredding of the aluminium scrap to re-melting, is performed with precision. Sorting is the first step in the process, in which aluminium scrap is separated from the mixed metal scrap stream. The dust, oil, and other impurities are also removed in this step. Once the aluminium scrap is sorted, it is then processed and made ‘smelter-ready’ to ensure a high purity level of secondary aluminium.

Non-availability of smelter-grade aluminium scrap remains the biggest challenge for the aluminium recyclers today. Even if they are procuring aluminium-rich mixed scrap (zorba), they have to sort it again and treat to a high degree of purity before it is ready to be used for smelting and fabrication.

Previously, sorting was done manually or by using non-automated machines but today, robotic picking and separating of aluminium scrap has made the entire process much speedier and cost-efficient.

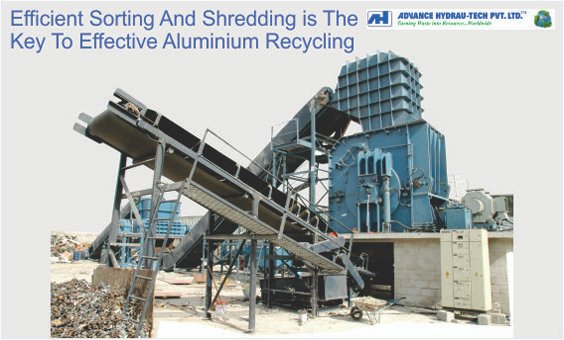

Shredding is the next step in the industrial recycling process that makes the metal scrap- the shavings, bands, wires, and cables melt-ready by reducing and reshaping them into desired shapes and sizes. Shredding is done by applying compression and robotic hammering.

Nowadays, advanced automated metal shredders are available which can use even contaminated metal scrap as input and the shredded scrap is then sorted using other mechanical sorting techniques like magnetic separation, air separation, eddy current separation or sink-float separation. In aluminium recycling, these machines first separate the ferrous and non-ferrous contaminants from aluminium scrap, and then, shear and cut the aluminium fractions into smaller pieces. The pieces are then fed into a decoater machine where the paint coating on the surface of the metal shreds is thoroughly removed. This technique ensures a higher purity level of the recycled aluminium.