Effective Agriculture Waste Management Is An Essential Aspect Of Operational Efficiency For Dairy And Cattle Farms In India. As The Industry Scales, Traditional Methods Of Handling Waste Will Become Increasingly Irrelevant And Will Be Replaced By High-density Compaction Technology. Many Innovative Companies Are Providing A Specialized Range Of Machinery That Is Designed To Convert Crop Residues Into High-value Fodder For Cattle. By Transforming Loose Straw Into Densified Blocks, Dairy Owners Can Ensure A Steady, Nutritious, And Cost-effective Feed Supply Throughout The Year. This Is Possible With The Help Of A Fodder Block Making Machine, Which Is All Set To Change The Way Indian Cattle Farms Approach Fodder Management.

The Product Lineup: Addressing the Waste Management Needs of the Agricultural Sector

There is a range of products available these days, delivering baling and block-making solutions to those working in the agricultural sector:

• Fodder Block Making Machine: These have high-pressure systems for creating nutrient-dense feed blocks, avoiding wastage and countering logistical issues.

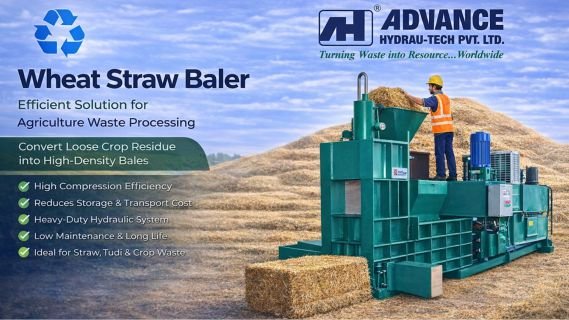

• Bhusa Baler and Straw Baler: Balers are specifically engineered for rapid compaction and tying up of wheat straw and other cereal residues.

• Rice Husk Baler: These machines are used to transform abrasive rice husks into manageable forms.

• Bhusa Packaging Machine: Used to enhance efficiency in commercial fodder supply.

• TMR Mixer: Uses an advanced process to create a perfectly homogenous mixture of straw, green fodder, concentrates, minerals, and molasses.

Understanding the Bhusa Block Making Machine

The Bhusa block making machine is also known as the feed block making machine or the fodder block making machine. It is a high-pressure hydraulic system designed to compress loose crop residue into compact, manageable, and uniform rectangular blocks.

While a traditional straw baler compresses the straw to a limited extent and ties it together, its role is limited. On the other hand, a block-making machine uses intense pressure to create a densified block.

With the use of modern-day innovation, these units are specifically engineered to handle the fibrous nature of Indian crop residues. The process is straightforward yet very effective. The straw is fed into the feeding chamber, compressed during the processing stage (including roughage, concentrates, and all other particles), and eventually takes the form of a solid block. The density is so high that there’s no need for excessive binding material, making it a pure and safe feeding option for livestock.

Advanced Machines: Their Key Applications in Dairy and Cattle Farms

Investing in a Bhusa baler or a feed block making machine isn’t just adding a piece of equipment to your facility; it is a strategic move for any dairy farm that wants to optimize its operations and gain huge profits. Here’s a closer look at the benefits these machines offer:

• Storage and Infrastructure Efficiency:

Loose wheat straw, rice husk, and other agricultural waste are low-density material (~50 kg/m3) that requires massive storage infrastructure. A Bhusa block making machine reduces the volume of the straw by 60% to 80%.

High-density blocks increase the storage capacity by 2.5x to 5x. This significantly reduces the capital expenditure required for building and maintaining large storage sheds.

• Logistical Cost Reduction:

Commercial fodder suppliers and dairy companies often see transportation as a major waste of money. A truck can carry only a limited volume of loose straw, which means the cost per kg of transport is very high.

By using an animal feed block making machine, the straw can be condensed, which allows trucks to reach their full weight capacity rather than just their volume capacity. This is a great way to reduce transportation costs significantly.

• Feed Utilization and Waste Minimization:

When cattle are fed loose straw, a significant portion is often trampled, blown away, or wasted in other ways. This leads to a lot of wastage and prevents proper feed utilization by the cattle.

However, when cattle farm owners have a Bhusa block, they can simply break it down into controlled portions that can be distributed accurately. This minimizes wastage during the feeding process, ensuring better ROI on feed purchases.

• Nutritional Integrity and Safety:

Loose straw attracts dust, pests, and fungal growth very easily. When it is converted into densified blocks, the surface area exposed to the environment is reduced. This helps preserve the nutritional quality of the fodder for longer periods.

Additionally, compressed blocks are far less flammable than loose heaps of straw, which reduces fire risks on the farm to a great extent.

Integrating a TMR Mixer with a TMR Block Making Machine

Nowadays, the dairy industry doesn’t just measure efficiency by volume but also by the nutritional value provided to the cattle. An animal feed block making machine isn’t specifically made for any one kind of raw material. It can handle a variety of agricultural residues, such as wheat straw, rice husk, jute fibres, etc.

A high-yield dairy farm can produce Total Mixed Ration (TMR) blocks with the use of a TMR Mixer and then transform them into densified blocks. The following process combines all the necessary nutrients into one complete mix:

1. The Mixing Stage: A TMR Mixer is used to create a perfectly homogenous mixture of straw, green fodder, concentrates, minerals, and molasses.

2. The Densification Stage: The specialized mixture produced by the TMR Mixer is then fed into the fodder block making machine.

3. The Result: The machine compresses the mix into a block that acts as a complete meal for the cattle.

Advance Hydrau Tech: Offering High-Performance Agricultural Waste Recycling Machines

With over 45 years of expertise, Advance Hydrau Tech has engineered the best high-performance machinery for agricultural waste management. The top pieces of equipment we have for the agriculture sector are:

• Fodder Block Making Machine

• Bhusa Packaging Machine

• Rice Husk Baler, Bhusa Baler, or Straw Baler

Our machines are built with precision, are easy to maintain, and operate smoothly even with high input volumes. Additionally, we understand that for a dairy farm, the machine's reliability is essential for cattle’s food security. That is why we have designed these machines so that operators can use them with ease, even after minimal training.

Conclusion

The Indian dairy farming industry is evolving from traditional, wasteful practices to a modern, mechanized fodder management approach. Fodder block making machines and balers are at the forefront of this revolution, giving dairy owners the ability to safeguard their facilities from fodder shortages, control their logistical costs, and improve the health of their livestock.

Whether you are a large-scale dairy farm owner or an agricultural entrepreneur, having the right machines is critical for unlocking growth. If you want to modernize your fodder management, you will find the most reliable machines at Advance Hydrau Tech.

Unlock sustainability and profits with Advance Hydrau Tech, contact us today for a consultation and a demo!